4.2.7.1. Coordinate systems

For the coordinates system not detailed in subsections below, please refer to the following references:

Technical report on FAST_AD and modeling of the UAE wind turbine (in section 3)

FASTCoordinateSystems.doc: Documents the transformation matrices relating each coordinate system in OpenFAST. Unfortunately, there are no pictures in this document that diagram these coordinate systems. They can hopefully be visualized by means of the transformation matrices.

4.2.7.1.1. Rotor-Furl coordinate system

The rotor-furl DOF allows the user to model the

unusual configuration of a bearing that permits the

rotor and drivetrain to rotate about the yawing-portion

of the structure atop the tower. The rotor-furl DOF can

alternatively be used to model torsional flexibility in

the gearbox mounting if the rotor-furl axis is aligned

with the rotor shaft axis. In order to include rotor-

furling in the model, the user must designate the turbine

as a furling machine by setting input Furling from the

primary input file to True. Then, the user must assemble

the furling input file, FurlFile, and use the rotor-furl

flag, RFrlDOF, to enable this feature.

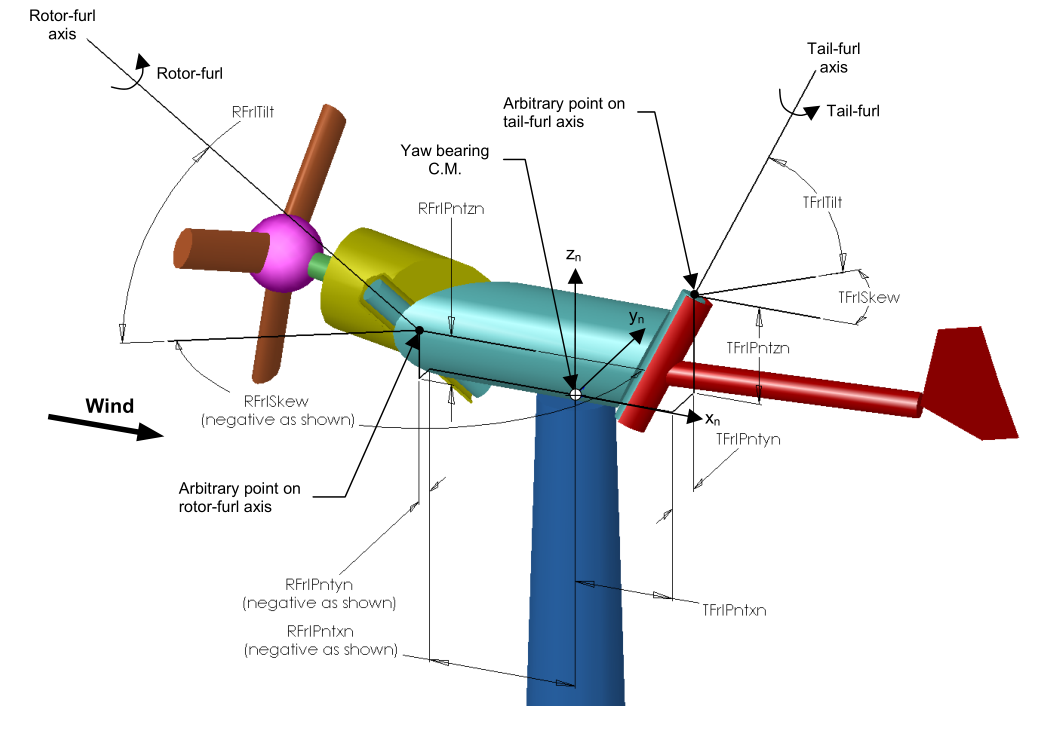

The angular rotor-furl motion takes place about the

rotor-furl axis defined by inputs:

RFrlPnt_n,

RFrlSkew, and RFrlTilt.

available in FurlFile.

The input RFrlPnt_n locate an arbitrary point on the rotor-

furl axis relative to the tower-top. Inputs RFrlSkew

and RFrlTilt then define the angular orientation of the

rotor-furl axis passing through this point.

See Fig. 4.45 for a schematic.

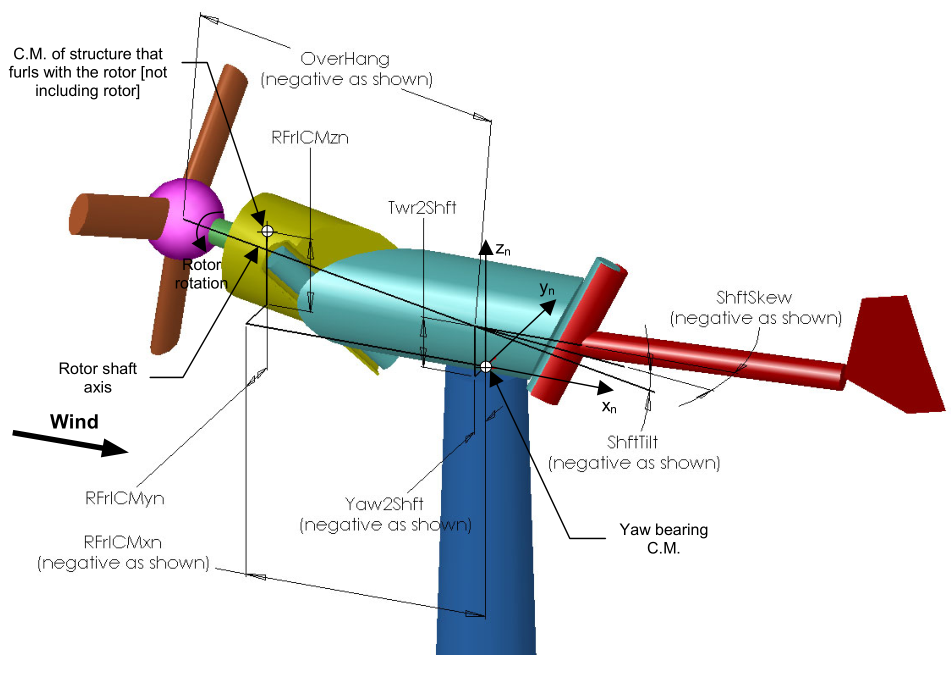

The geometries of the hub and rotor-furl structure mass center, which are both components of the furling- rotor assembly, are defined relative to the tower-top as shown in Fig. 4.46. This definition was chosen in order to avoid having to define a coordinate system in the furling-rotor assembly since such a coordinate system would most likely have an obscure orientation, making it difficult for users to input configuration information relative to it. This definition also avoids the complications involved in having to define geometries differently, depending on whether or not a rotor-furl assembly exists separately from the nacelle, which depends on whether rotor-furl is present or absent in the turbine.

Since the component geometry of the furling-rotor assembly is defined relative to the tower-top, this geometry naturally changes with the rotor-furl angle. In order to avoid having to define different geometries for different rotor-furl positions (for example, variations in the initial rotor-furl angle), ElastoDyn expects the component geometry of the furling-rotor assembly to be defined/input at a rotor-furl angle of zero. As such, the initial rotor-furl angle does not affect the specification of any other rotor-furl geometry. Stated another way, the input geometries for the rotor-furl assembly components define the rotor configuration when the rotor-furl angle is zero regardless of initial rotor-furl position. Users should be clear of this convention when assembling their furling input file.

4.2.7.1.2. Tail-Furl coordinate system

The tail-furl DOF allows the user to model the unusual

configuration of a bearing that permits the tail to rotate

about the yawing-portion of the structure atop the

tower. In order to include tail-furling in a model,

the user must designate the turbine as a furling machine by

setting the input Furling from the ElastoDyn input file to

True. Then you must assemble the furling input file,

FurlFile, and use the tail-furl flag, TFrlDOF, to enable

this feature.

The angular tail-furl motion takes place about the

tail-furl axis defined by inputs TFrlPnt_n, TFrlSkew, and TFrlTilt available in

FurlFile.

The input TFrlPnt_n locate an arbitrary point on the tail-furl axis

relative to the tower-top.

See Fig. 4.45 for a schematic.

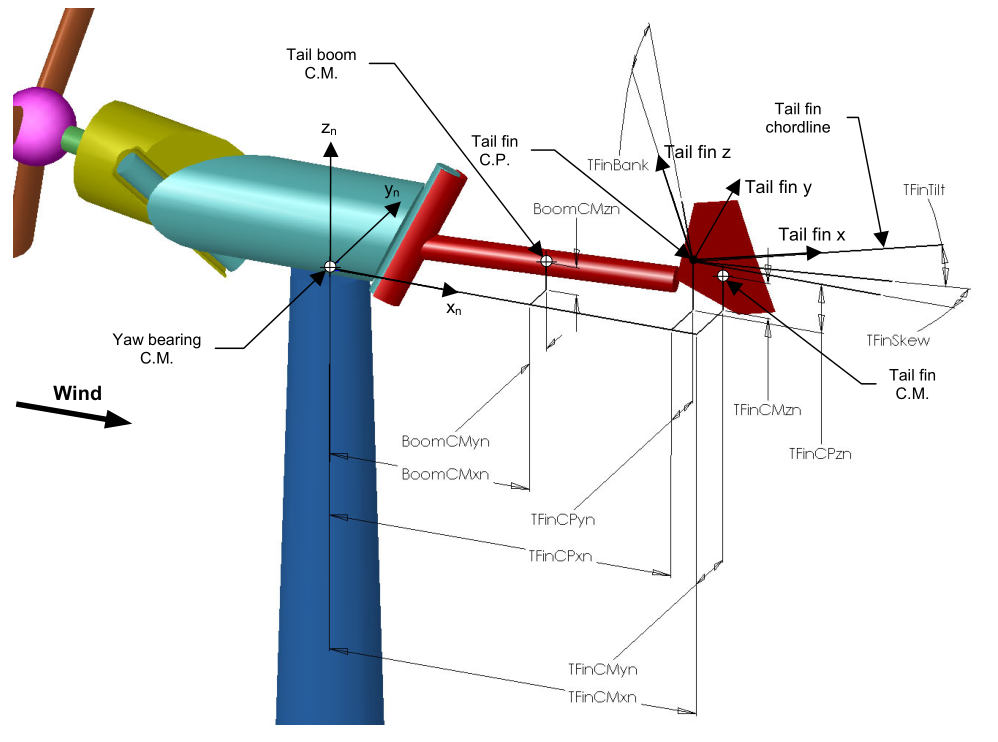

The geometries of the tail boom mass center, tail fin mass center, and tail fin aerodynamic surface, which are all components of the furling-tail assembly, are defined relative to the tower-top as shown in Fig. 4.47. This definition was chosen in order to avoid having to define a coordinate system in the furling-tail assembly since such a coordinate system would most likely have an obscure orientation, making it difficult for users to input configuration information relative to it. This definition also avoids the complications involved in having to define geometries differently, depending on whether or not a tail-furl assembly exists separately from the nacelle, which depends on whether tail-furl is present or absent in the turbine.

Since the component geometry of the furling-tail assembly is defined relative to the tower-top, this geometry naturally changes with the tail-furl angle. In order to avoid having to define different geometries for different tail-furl positions (for example, variations in the initial tail-furl angle), ElastoDyn expects the component geometry of the furling-tail assembly to be defined/input at a tail-furl angle of zero. As such, the initial tail-furl angle does not affect the specification of any other tail-furl geometry. Stated another way, the input geometries for the tail-furl assembly components define the tail configuration when the tail-furl angle is zero regardless of initial tail-furl position. Users should be clear of this convention when assembling their furling input file. Further clarification on this furling geometry convention is provided in the Rotor- Furl section above.

Fig. 4.45 Layout of a three-bladed, upwind, furling turbine: furl axes

Fig. 4.46 Layout of a three-bladed, upwind, furling turbine: rotor-furl structure

Fig. 4.47 Layout of a three-bladed, upwind, furling turbine: tail-furl structure. NOTE: The tail fin “CP” (center of pressure) parameters are now replaced by the location of the reference point.